|

In kite surfing /

kite boarding the steering bar allowes the surfer to control the motion

/ flight of the kite and connects the kite surfer to the kite. The bar

is moved in an left/up and right / down motion ( or some call it boxing

) or opposite by the surfer to steer the kite left or right .

The inner lines ( break lines / flight lines / power lines) are

attached to the harness via chicken loop and by pushing the bar away

from the surfer he can depower the kite. This setup would be tiering

over time on our kite-sailer.

As such we need to change this setup to a more comfortable moition. Our

kite control bar will direct the forces of the inner lines ( the power

lines / break lines / flight lines) to the hull via a 1:2

reduction with quick release. The outer lines ( steering lines / flying

lines) will be 90 degree redirected to the controller handle bar

which has a left-forward / right-aft ( or opposite) motion to steer the

kite actively from a sitting position on the kite-sailer.

Since the kite-sailer kite control bar will be used on a boat and its

intention is to use it for extended periods of time, in a saltwater

environment, all components used are marine grade stainless steel and

can handle the loads of modern traction kites. Safe working load was

set at excess of 500lb .

kit

Back to main page.

|

|

|

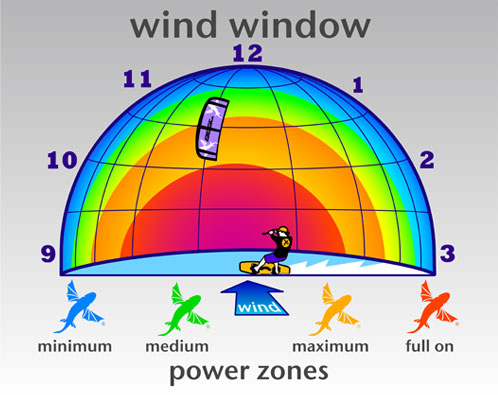

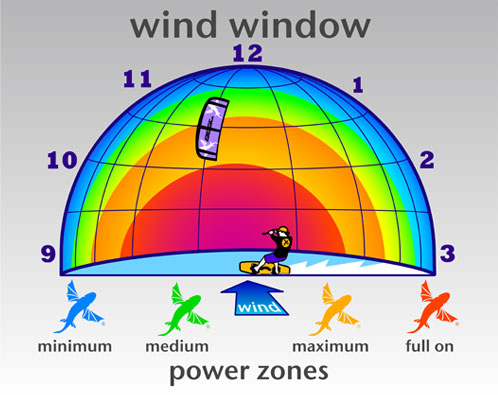

The "Wind Window" and forces of the kite :

align="left"> I want to add

this short explanation for all who are coming from boating / sailing to

this site and are not familiar with the expression "wind window" and

the forces behind it. Kite surfer are well familiar with the forces and

master them to their benefit.

The "wind window" as seen on the right side is if you are standing with

your back into the wind ( upwind ) and face away from the wind (

downwind) . The 3-dimensional area in front of you and within the reach

of your kite - kind of limited by the length of the kite lines which

are normally about 20 meter / 64 feet. Each section of the "wind

window" has a different force on the kite , different acceleration of

the kite and diffrent pull / lift characteristics. The upwind section

of the "wind-window" or for sailor the circle of "Beam reach " has the

lowest amount of force / lift / pull and the slowest motion of the

kite. As you steer your kite into the center of the "wind window" or

downwind / run the forces will increase drastically as well as the

speed of the kite as it is moving through your wind window. To balance

the motion and the forces of the kite through the "wind window"

requires an open area in front of your kite to hull attachment point as

well as a free space for the kite controller to maneuver the kite

control lines, besides attention and quick reaction so you don't ditch

your kite in the water.

As you actively steer your kite through the wind window you can make

use of the diffrence between pulling forces and lifting forces to

balance your hull with the motion of your kite.

Back to main page.

|

|

|

Connecting the kite to the hull

Most modern

traction kites are 4 line kites - this results into 2 power lines at

the kite and 2 steering lines. The power lines are more to the center /

forward of the kite while the steering lines are aft / on the trailing

edge of the kite.

The power lines can be connected at the hull into one line - while the

2 steering lines need to stay independent from each other for control.

Power lines need to be easy adjusted for setting the kite canopy angle

for your convenience and in case of a emergency to be depowered - (

released) which results in a airfoil shape with 0 lift.

You can accomplish this with a pulley on a line leading back to a cam

cleat at the same location where you will steer the kite.

Steering lines need to be able to adjust ( via a bar ) or any other

means to pull or release. This will steer your kite and fly him through

the power window in a controlled manner -

The image on the right is from a Airrush one 4 line kite with only one

bladder and steering lines well apart from the power lines - I believe

for us a bit slower moving kite-boater this set up is better than the

older C-shape kites where power lines and steering line attachemnt

points are within 8 "

I hope I could help you understand the basic setup for kite boating -

if you have any question feel free to ask michael@4wings.com

Back to

main page.

|

|

|

May -

A new set of pulleys came in

and they fit great - low weight / swivel head and ball bearings in our

working load range -

This is the core of a long discussion we had when we tried to find the

best suitable lines for the kite-sailer control bar.

For kite control lines you need lines with low diameter ( to hold drag

low ) , low weight and high "Tensile Strength"

On the control bar you will need high tensile strength but can be

more flexible on the diameter.

Tensile strength is the load at which a new rope / line , tested under

laboratory conditions, can be expected to break.

Safe working load of a rope / line is determined by dividing the

minimum tensile strength by the safety factor .

Safety factors range from 5 to 12 for non critical uses. The safe

working load is a guideline for rope/line in good condition.

With age and use, the safe working load of your kite

rope / line will get lower.

So lets get out of the theory and start to look at the Kite lines and

control bar lines -

Currently common kite lines are "Dyneema SK75-12" or "Dyneema sk90"

Alternatively you can use :

"Spectra"which is used by some kite manufacturer and

"Vectran"

"Spectra" and "Dyneema" are the same material

Ultra-high-molecular-weight polyethylene , just different trade names

and the manufacturing process is different.

"Vectrans" are some form of liquid crystal polymer that have similar

strength, but higher modulus and less creep. for more detail please see

:

http://www.performancedesigns.com/hma.asp

If you are in the EU / Asia

you might look into Liros lines : http://www.liros.com/start.aspx

Kevlar ( aramid) fibers are

still as strong as spectra but higher in density.

You'll frequently see fibers compared with strength / weight as the

ultimate value.

But this is not necessarily stronger, but stronger per unit weight as

such you need to make the numbers till the end ....

Diameter and tensile strength of Dyneema SK75-12

Avg. Tensile strength for 1.8 mm - 920 lbs

Avg. Tensile strength for 2mm - 1000 lbs

Avg. Tensile strength for 3mm - 1920 lbs

For most user the kite lines provided by the kite manufacturer will be

your best choice - as one of the main problem is to find a supplier who

has the quality you need , the diameter you desire - in the colors you

want at a price you can afford ...lol in a line diameter of 3 mm and up

you will find a small amount of supplier - unfortunately that diameter

is a bit to high - you will try to be in the 1.5 mm to 1.8mm (

approximately 1/16" ) diameter

range of lines for your flying lines -

For your kite control bar the lines can be in the 3mm ( approx. 1/8"

) and 6 mm ( approx. 1/4") range as these lines are not all too

much subject to drag but quite some chaffing.

All the lines should be eye spliced to hold the maximum breaking

load throughout the entire line which is possible on the 6mm up lines

but hard on anything below this diameter.

The only supplier we found who actually carried more than one color and

diameter was : http://www.milwaukeerigging.com/index.htm

But we hope that over time we will

have more suppliers for you

Back to main page

|

|

|

April -

We get most of the components

ready to go into the first test trial - test were performed at our dock

with a 3.5 meter trainer kite to get the basic feel for the bar - even

if the functions performed well - the pulleys were too big

and the lines too heavy - guess I have to get the sailor out of

me and rethink thin ...how thin ..?

Back to main page

|

|

|

March -

Kite-sailer kite control bar

extended

Back to main page

|

|

|

March -

Just out of the welding shop -

The basic components are a SS square bar with welded support for the

cam cleat on top which will serve as de-power system / de-power

adjuster.

The fork swiveling snap shackle serves as emergency release and

connects the handle bar to a lifting eye which is through-bolted the

boat hull and secured with a 5/8 SS bolt

A pivot point for the handle bar is welded to the outer piston sleeve

which will connect the outer ( steering ) lines.

Back to main page

© 2012

kite-sailer.com

|

|